Modern leak detection have evolved beyond rudimentary visual inspections and rely on sophisticated techniques to pinpoint even the smallest of fluid escapes. Ultrasonic sensors, for example, can identify minute vibrations caused by escaping liquids or gases, providing real-time monitoring and alerting systems. Infrared thermography offers another effective tool, as it detects subtle temperature differences that may indicate leaks, even in hard-to-reach areas. Advanced software algorithms can then analyze the gathered data, providing precise leak locations for targeted repairs and minimizing potential impact. By embracing these cutting-edge methods, industries can achieve greater efficiency, reduce environmental impact, and ultimately optimize their operations.

Reducing Water Consumption: Finding Leaks

Leaky faucets, dripping pipes and running toilets can quickly add up to significant water waste. By learning how identify leaks promptly, you can reduce water and diminish your utility bills. Start by thoroughly inspecting your plumbing fixtures for any signs of dampness. Check under sinks, around toilets and in basements for pools of water. A good leak detection way to uncover leaks in pipes is by checking your water meter reading. If the meter moves while no water is being used, it indicates a leak somewhere in your system.

- Consider installing low-flow faucets and showerheads to greatly reduce water consumption.

- Periodically inspect your plumbing for potential problems and address them promptly.

- Call a licensed plumber if you believe there is a major leak or if you are unable to find the source of the problem yourself.

Subtle Perils: Detecting Secret Water Leaks

Water damage can be a serious problem, but many leaks go undetected for weeks, even months. These discreet threats can cause costly repairs and structural problems. Identifying prompt signs of a leak is crucial to preventing major catastrophes.

- Scrutinize your plumbing fixtures regularly for any indications of leaks, such as drips or water stains.

- Monitor your water bill for unexpected spikes in usage.

- Check areas prone to moisture buildup, like ground floors, bathrooms, and kitchens.

If you observe a leak, respond quickly to minimize damage. Reaching out to a qualified plumber is the best way to ensure the problem is fixed effectively.

Preventing Industrial Leaks

In today's dynamic industrial landscape, ensuring operational safety and efficiency is paramount. One critical aspect often overlooked is the potential for spills. These result in significant disruptions, impacting both financial stability and environmental well-being. Utilizing effective industrial leak detection solutions is therefore essential for minimizing operational impact. By pinpointing leaks in a timely manner, businesses can mitigate the potential for incidents and maintain a secure operating environment.

Regular inspections are crucial for identifying potential leak sites. These assessments should be conducted by trained professionals who can thoroughly inspect equipment, pipelines, and storage tanks for any signs of compromises.

Cutting-edge monitoring systems offer a more reliable approach to leak detection. These systems can proactively assess pressure changes, temperature fluctuations, and gas concentrations to identify even the tiniest leaks before they become a major problem.

By implementing a comprehensive industrial leak detection strategy that combines both standard procedures with advanced technologies, businesses can significantly improve their operational safety, efficiency, and environmental compliance.

Techniques for Leak Prevention in a Sustainable Future

Preventing leaks is crucial for a sustainable future. Industrial processes often generate significant amounts of waste and emissions. Minimizing these leaks can have a beneficial impact on the environment and conserve precious assets.

A integrated approach to leak prevention includes several key strategies. These include implementing sophisticated detection tools, training employees on discharge mitigation practices, and systematically monitoring equipment for potential problems.

Additionally, adopting sustainable practices throughout the manufacturing process can significantly minimize leakages. This includes optimizing workflows for effectiveness, recovering waste materials, and incorporating sustainable systems wherever possible.

By implementing these leak prevention strategies, we can move towards a higher sustainable future with minimal environmental impact and improved resource utilization.

The Science of Leak Detection: Sensors, Technology, and Expertise

Uncovering hidden water is a critical task in various industries, requiring advanced techniques. The science of leak detection relies on a mix of innovative devices and expert evaluation to pinpoint the source and extent of the problem. Sophisticated sensors, such as ultrasonic probes and acoustic emission detectors, pinpoint subtle changes in pressure, vibration, or sound that indicate a leak.

These signals are then sent to specialized programs for analysis and interpretation. Experts in the field employ their knowledge of flow patterns to correlate sensor data with potential leak locations.

Through a systematic process, involving site investigations, evidence gathering, and modeling, leak detection specialists effectively identify the source of the problem, minimizing damage and ensuring efficient repair.

Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Barry Watson Then & Now!

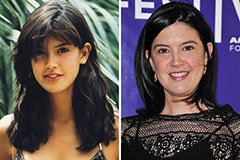

Barry Watson Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!